Vessel Modification, Retrofit and Conversion

Home » What We Do » Ship Design »

Service Introduction

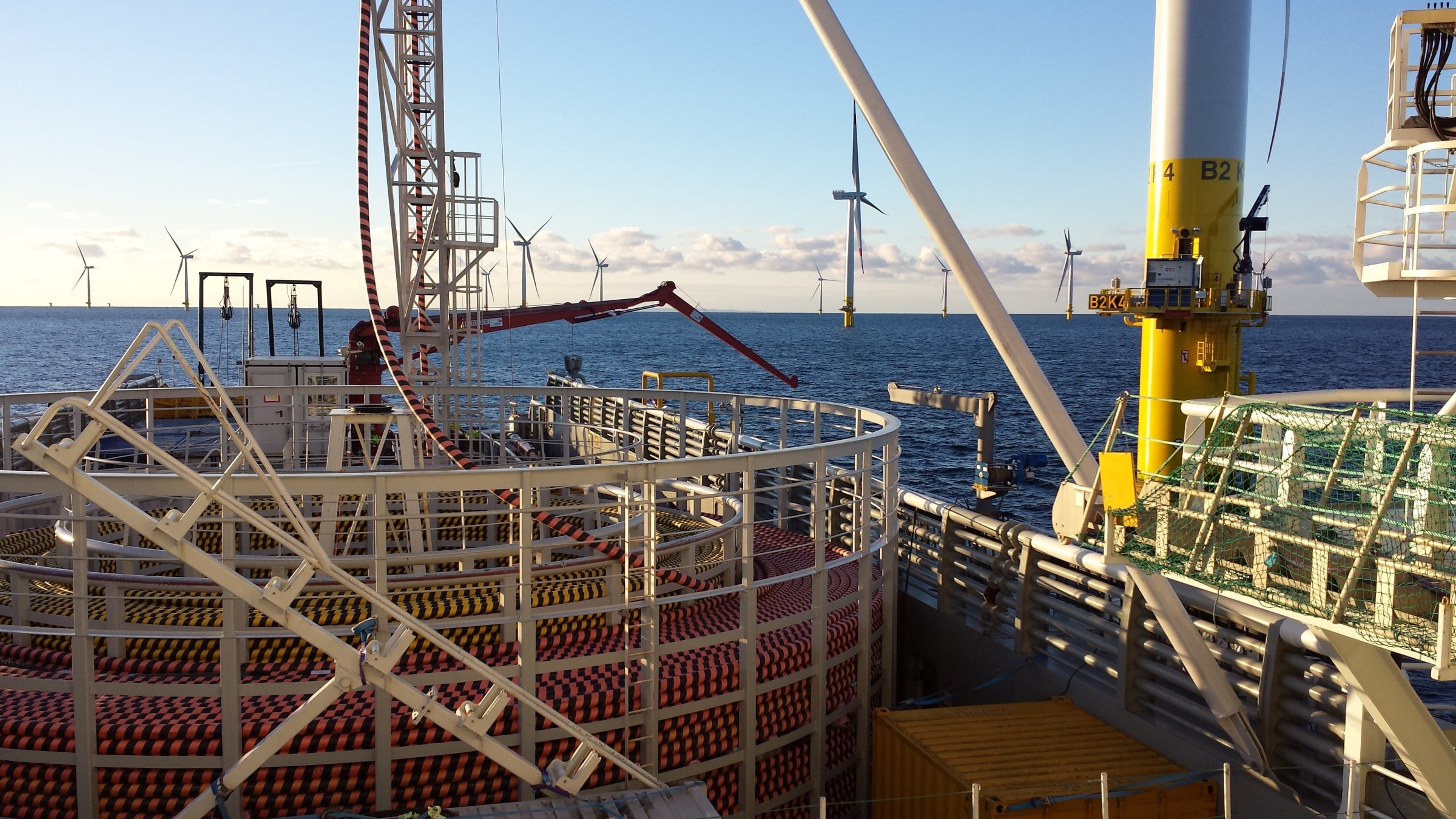

From modifications to major conversions and retrofits, Longitude brings extensive experience in the design and engineering for vessel upgrades of all types, sizes and purposes.

Whether to achieve enhanced vessel capability or to fulfil an entirely new role, Longitude work with clients to determine the feasibility and scope of modification and conversion, through to fully engineered conversion packages and in-yard support, with a focus on your requirements. Our approach and processes are adaptable and tailored to each client and each project.

Longitude combines our legacy of +30 years of experience in ship design, our roots in naval architecture, structural design and analysis, and marine systems’ design. Our offering also benefits from the extensive knowledge in marine assurance and risk, marine operations, class and flag requirements, both within Longitude and through our sister company, the energy and marine consultants, ABL.

Our diverse track record includes the following vessel conversion projects:

- Conversions of platform supply vessels and anchor handling tugs to safety-standby vessels

- Conversion of a platform supply vessel to an Ocean Terminal Support Vessel

- Modifications to add cranes, davits and other lifting equipment

- Small cargo ship conversion to trailing suction hopper dredger

- Cargo ships converted to cement carriers

- “Dumb” barge to a self-propelled cable laying and maintenance vessel

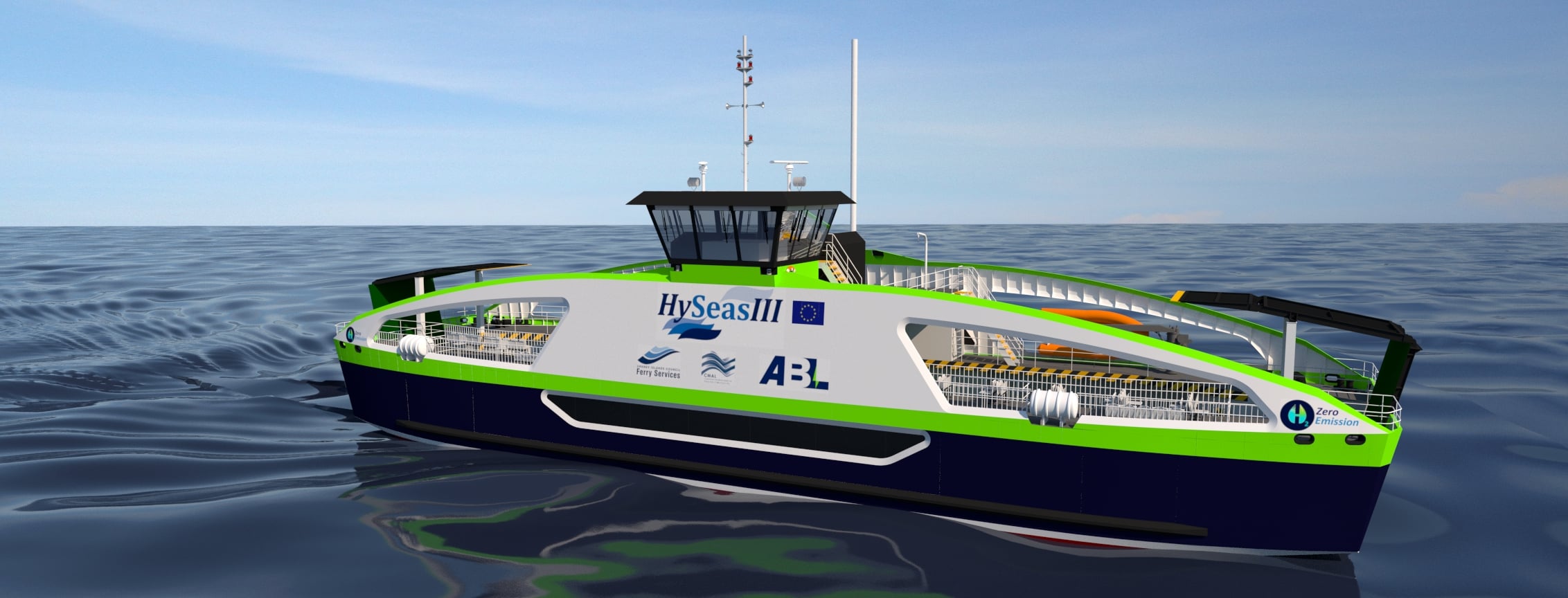

- Lengthening of an aluminium catamaran crew transfer vessel

- Conversions to oceanographic research vessels

Vessel Modification, Retrofit and Conversion Market Challenges

- High costs and CAPEX pressures – Investment in modification and conversion must be targeted to deliver the required capability in a cost-efficient manner, considering CAPEX, OPEX and vessel-derived revenue

- Project timelines for design and implementation may be short and driven by vessel and yard availability

- Ensuring regulatory compliance as well as environmental regulations

- Keeping pace with technological advancements, while mitigating the risk of the unknown

- Risk of incorporating new technological advancements and ensuring ongoing regulatory compliance

Our Vessel Conversion Services

Our multi-disciplined service offering covers:

- Stability

- Manoeuvring analysis

- Loading computers

- Design

- Concept and basic design

- Computational Fluid Dynamics (CFD)

- Statutory review and compliance

- Life extension

- Structural engineering

- Alternative fuel engineering and electrification services