Moorings, Cables and Umbilicals

Home » What We Do » Marine Operations »

Service Introduction

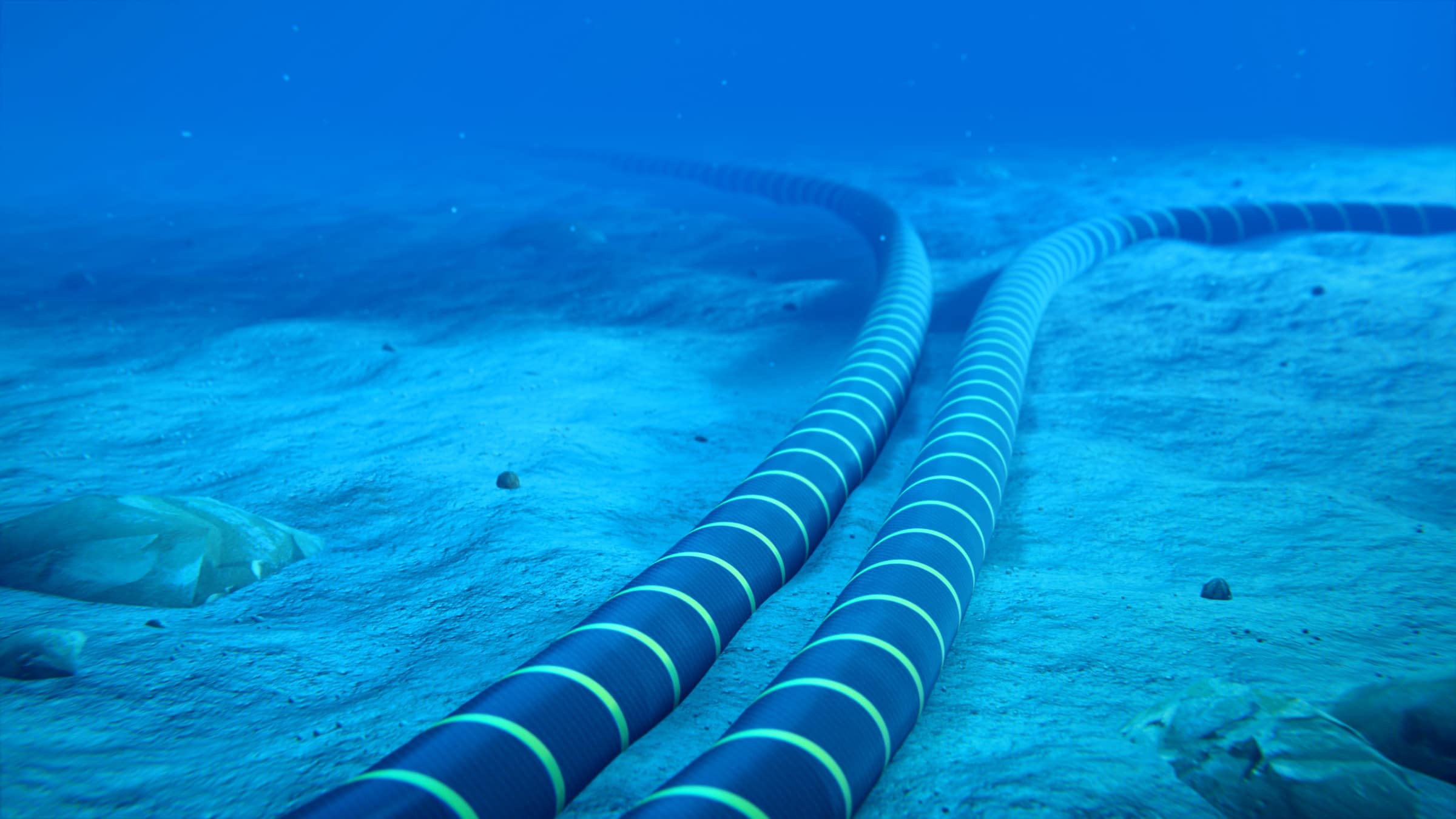

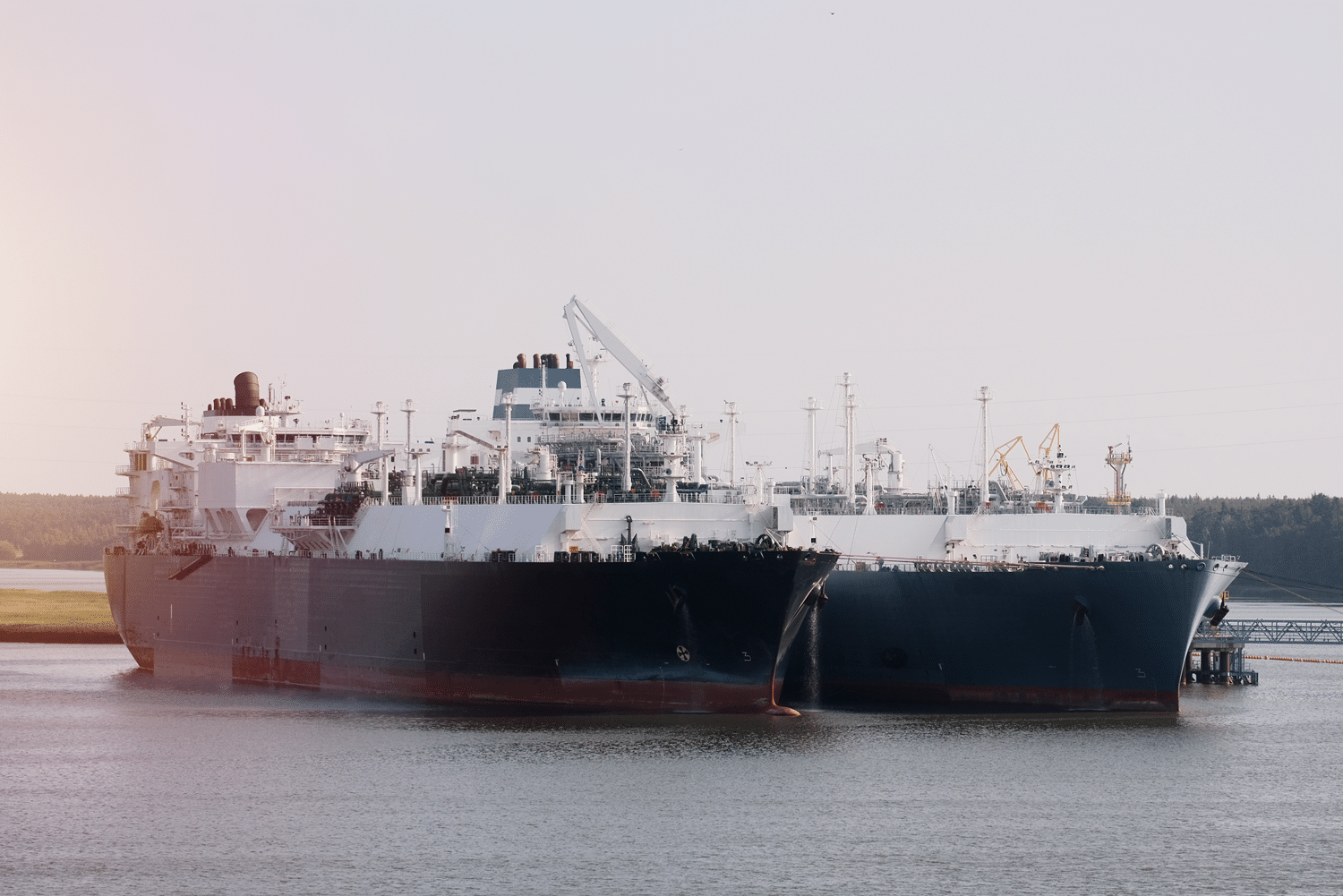

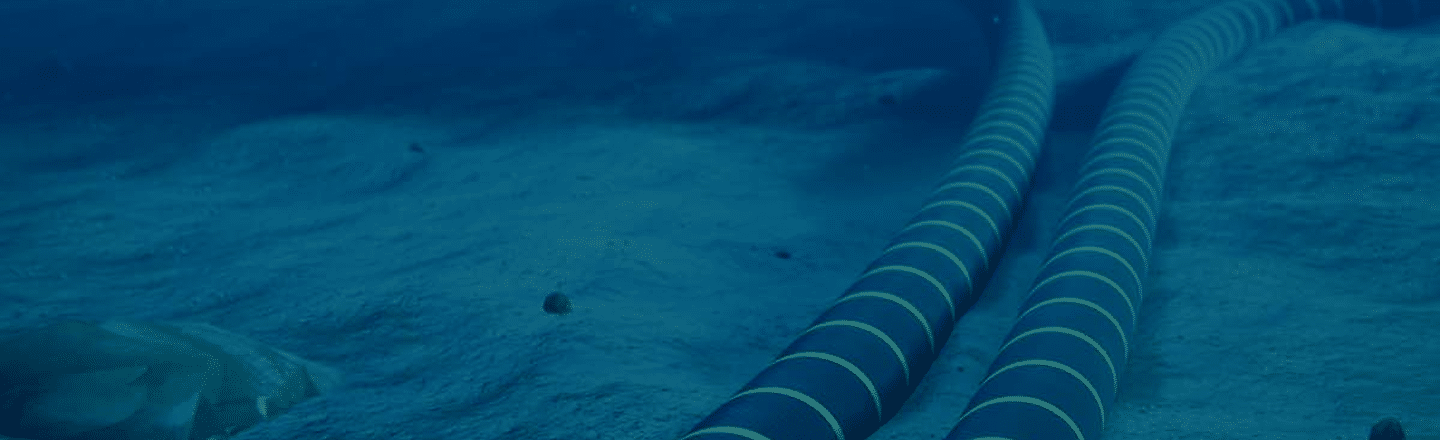

Robust, efficient and cost-effective subsea infrastructure, such as moorings, subsea power cables and umbilicals, is critical to offshore construction operations and future energy production. Exposed to the hostile elements of subsea conditions, increasingly congested marine spaces and unique environmental conditions of new geographies, these subsea assets require careful and comprehensive engineering at their original installation to support their long-term performance.

Longitude is a market-leading provider of marine operations design and engineering services to support all types of moorings, subsea cables and umbilicals.

Our global and cross-sector experience, built up since 2006, places us uniquely to understand the diverse risk profile that may impact the durability and effectiveness of these assets. We also employ our extensive knowledge in different vessel types and operations to help clients in making design decisions for the long-term, driving value to your bottom line.

Moorings, Cables & Umbilicals Challenges

- High installation and maintenance costs:

Detailed and advanced risk mitigation at installation can reduce the risk of future maintenance requirements. - Resilience against harsh environmental conditions:

With an increasing risk profile as projects go further offshore and into new geographies. - Supply chain bottlenecks and logistical challenges:

Causing delays in installation and impacting CAPEX and OPEX. - Technological advancements

And new risks that these entail if not properly tested and inspected. - Congested navigation and busier marine spaces:

Raising the risk profile to subsea assets, if not properly analysed, identified, and mitigated against.

Our Services: Subsea Cables & Umbilicals

Longitude provides the services that our customers require to fulfil their mission of designing cable routes and understanding risk to subsea installation, vessel mobilisation, cables’ protection, maintenance and repairs for offshore wind projects and subsea interconnectors.

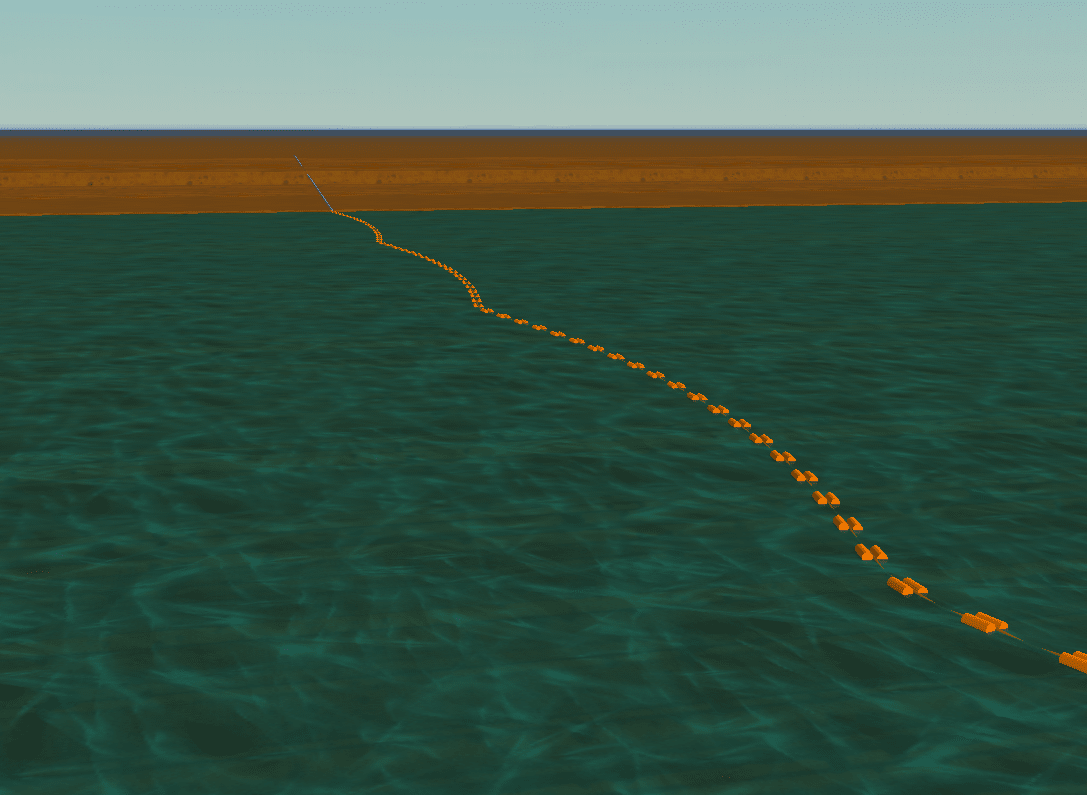

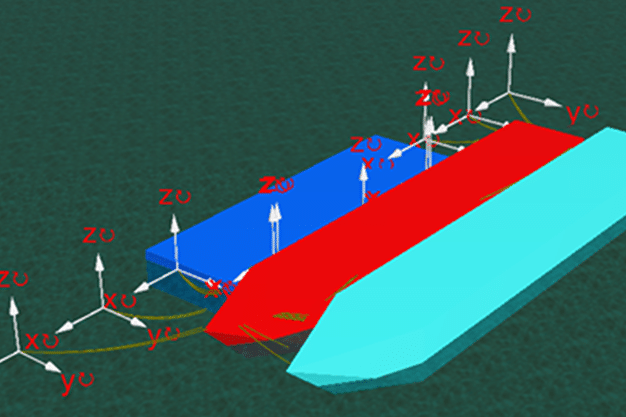

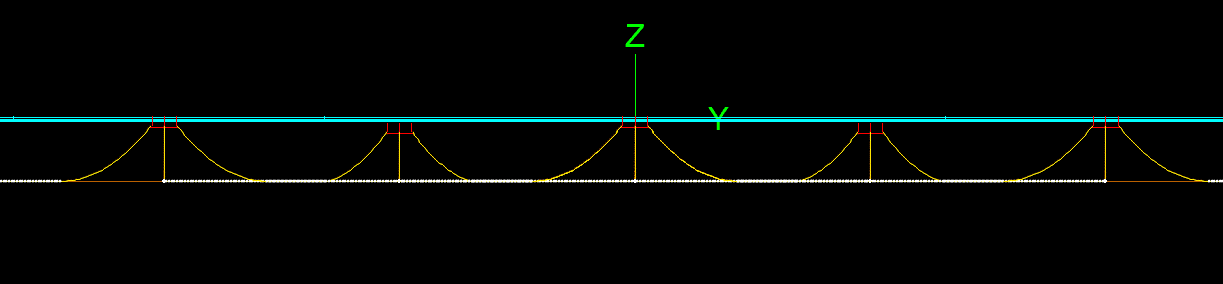

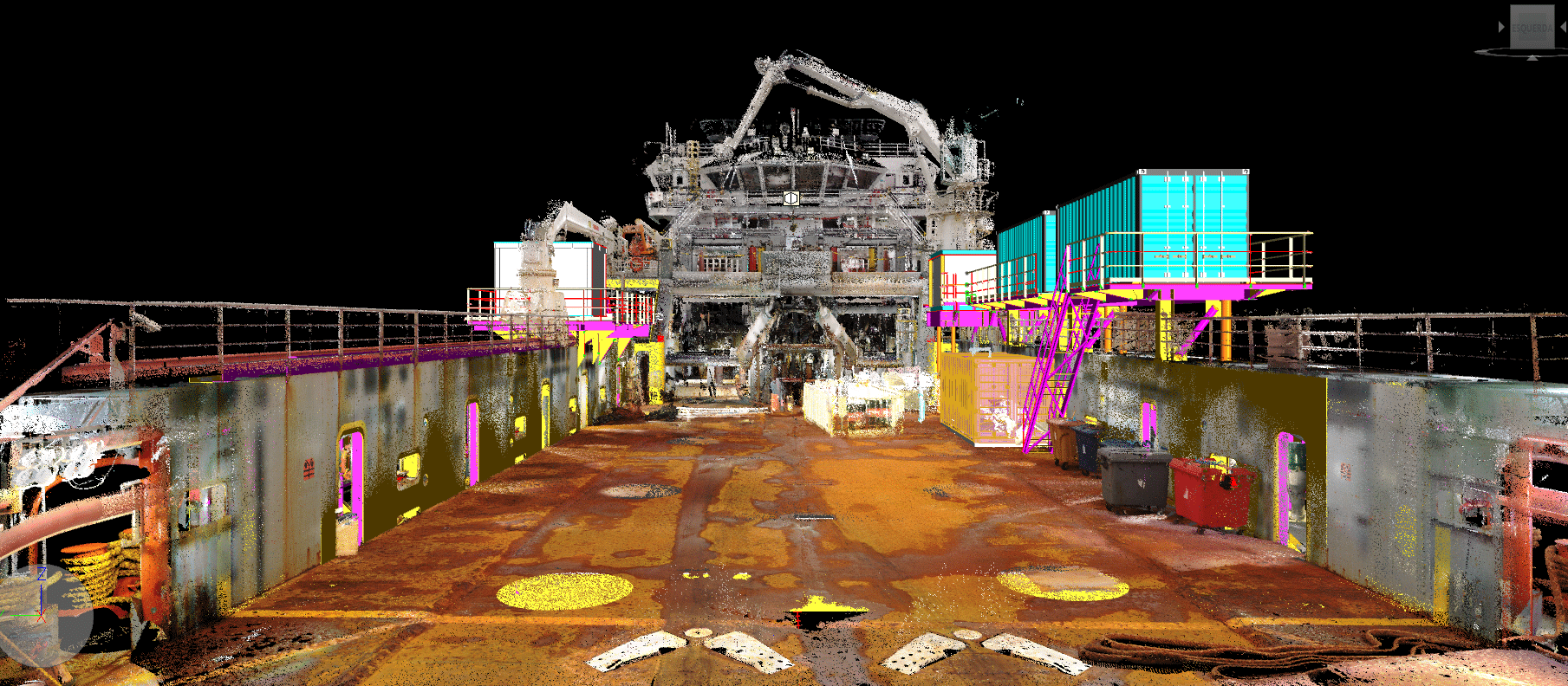

Our operationally-focused submarine cable installation services include skidding moorings, cable lay and pull, analysed in simulations using Orcaflex – the industry-standard software applied to these operations.

Longitude has also developed its own tool for automating the pre- and post-processing of cable installation analyses, allowing us to handle an increasing number of environmental cases.