Longitude Engineering has developed a cost effective decommissioning barge concept for the safe removal of small oil and gas platforms for the PTT Exploration and Production (PTTEP), a subsidiary of the Thai state owned oil company.

The primary aim of the works was to develop a viable and cost-effective alternative to conventional ‘reverse installation’ through the use of heavy lift crane barges, for the removal of the topsides and jackets. The focus being the removal of 90-100 of PTTEP’s minimum facilities platform assets in the Gulf of Thailand, which have topside weights up to 800 tonnes and jacket dry weight up to 1000 tonnes.

Longitude’s contract was to deliver the conceptual naval, structural, mechanical and electrical engineering, along with outline operational procedures, schedule and CAPEX & OPEX costing for the new removal concept.

The technical solution:

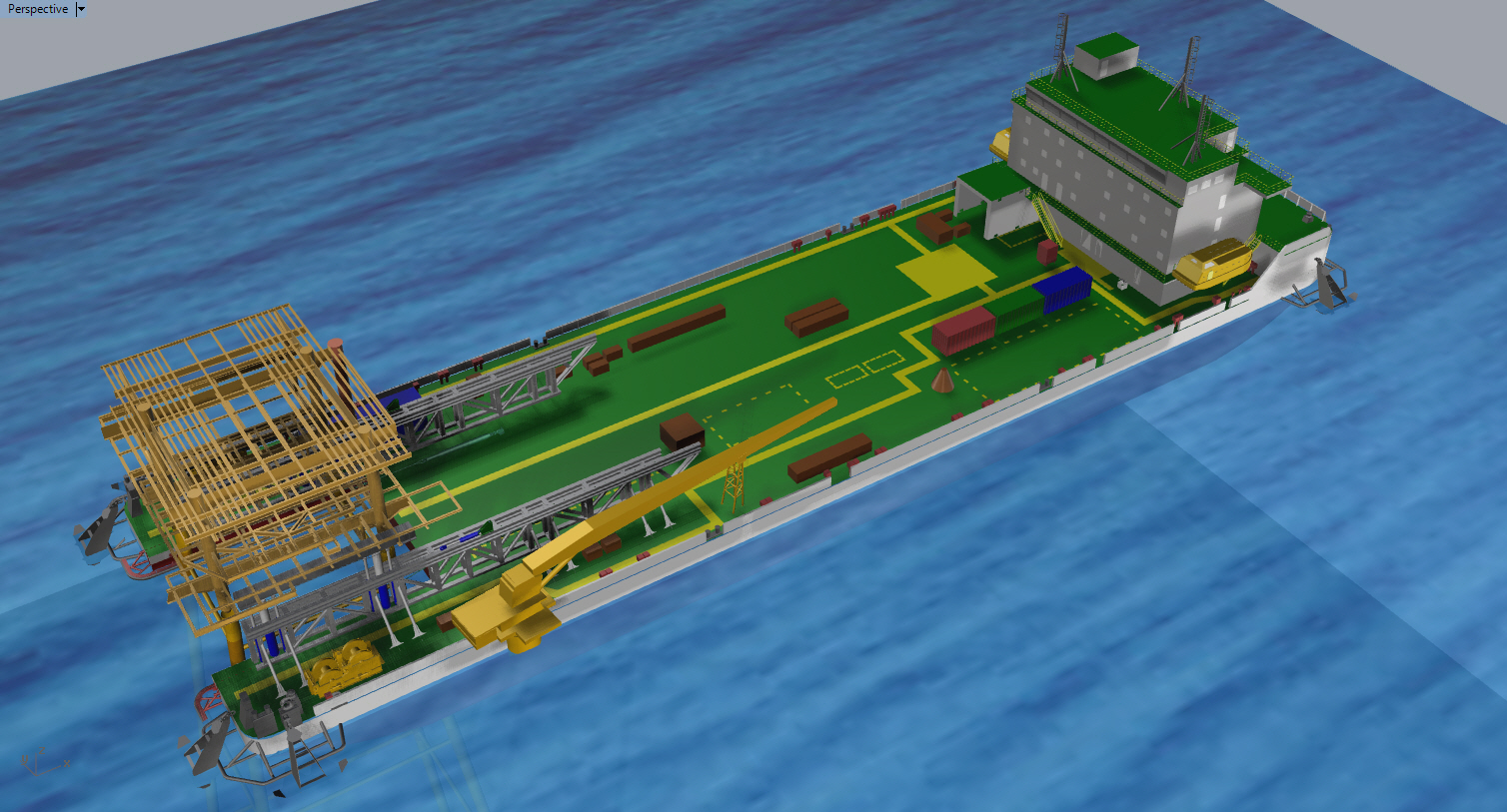

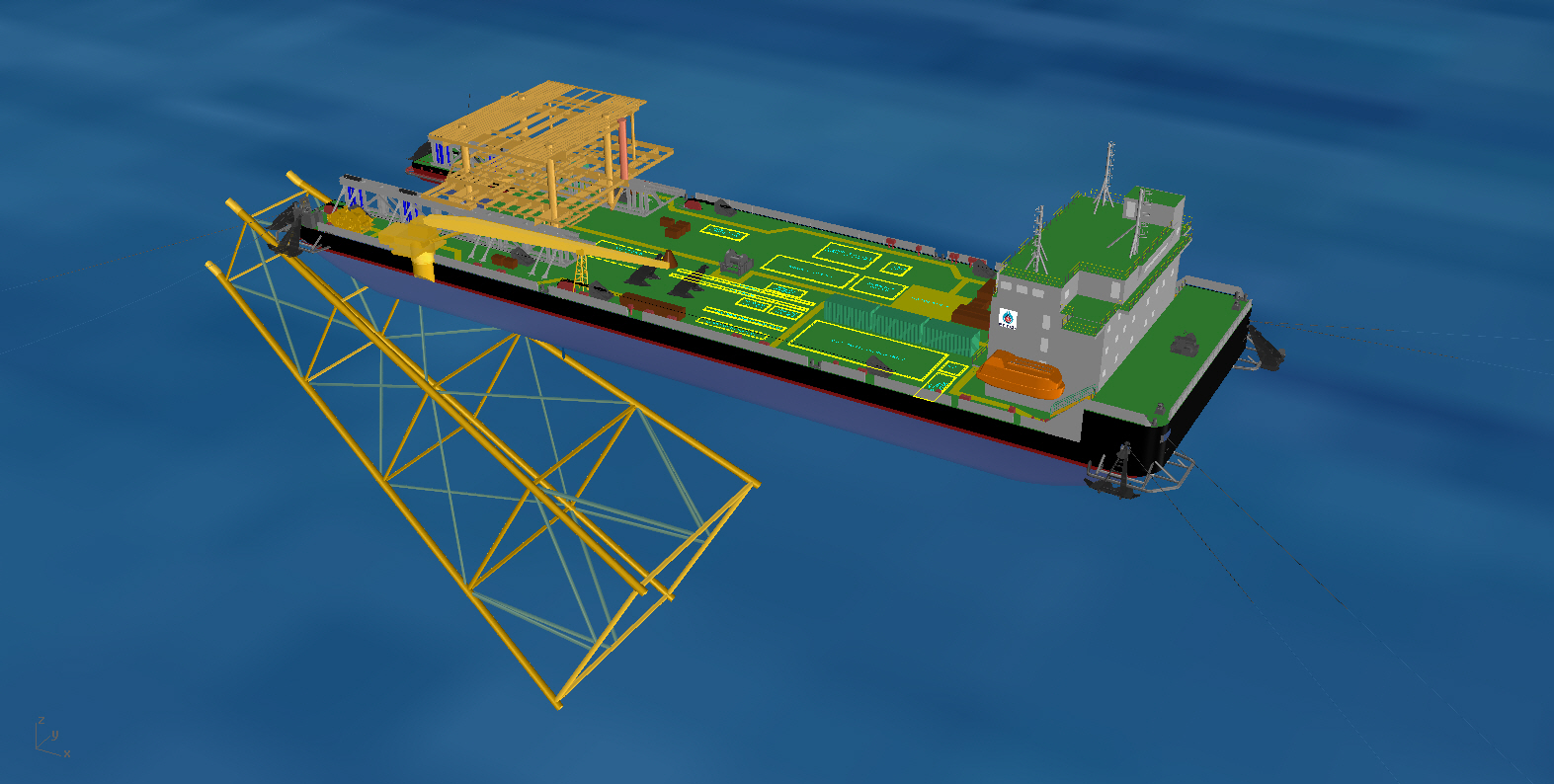

The developed solution is a barge concept that utilises reverse float-over and on-board lifting methods to remove both the topside and substructure utilising the same vessel.

For the development of the primary float-off lifting system, Longitude partnered with German-based hydraulics specialist, Bosch Rexroth, to develop a heave compensated hydraulic lifting and skidding system.

The resulting vessel design can accommodate the removal of different types of topsides and jackets, without modifying the barge, from removal preparation stages, lifting, topside skidding and securing to underwater disposal for the substructure and load in to a disposal yard for the topside. It also has the ability to accommodate 60 operational and marine crew for a period of up to 40 days.

The engineering performed to support the chosen technical solution comprised the Naval design, the definition of the operational weather windows, the development of associated vessel layouts, the Structural design, the Mechanical systems design, the Marine system design and the Electrical systems definition.

Delivery also included various philosophies covering aspects from the Health and Safety to material handling and Flag/Rules/Codes and standards analysis.

Finally, a full set of preliminary operational procedures were developed for lifting operations, transport, load-in along with associated operational schedules and associated CAPEX and OPEX costings.

The schedule and cost considerations:

PTTEP is currently in discussion with Thailand’s Department of Mineral Fuels (DMF), the government body regulating offshore oil and gas operations, which will sanction the decommissioning work, for the start of their removal programme which is due to commence in the coming years.

With the implementation of new decommissioning regulations, all concessionaires must submit the decommissioning plan with cost estimation to DMF for financial security placement at the first stage. The evaluation and reporting on the expected schedule and associated cost for the operations being a critical part of the decommissioning process, a cost effective decommissioning barge is favoured.

According to Longitude’s lead engineer Jean-Baptiste Meier: “By developing this time and cost-saving solution, we hope to create a wider awareness among contractors within the region in order that they may adopt similar methods in the removal of multi -platform fields.”

He added: “The South East Asian fields present many similar small platforms where innovative thinking can be used to make an economy of scale in the removal operations”.

It is crucial to clearly define the standards and procedures for the decommissioning work in the Gulf of Thailand – to ensure that the solution is not only the most innovative and cost-efficient but also environmental friendly.

While pending approval from DMF, PTTEP has logged a petty patent for this solution.