Longitude was contracted by BW Offshore to provide the full range of naval architecture and structural engineering service for the detailed design of the conversion of a tanker to a Floating Production Unit (FPU) for operation in Terang Sirasun Batur, offshore Indonesia. The vessel was considered a FPU, but also has a storage and offtake capability for produced condensate.

Facts and Figures:

- 235m Vessel LBP

- 42m Vessel Breadth

- 12-points spread mooring system

- ABS Class

Engineering scope:

Longitude’s involvement with the project started as soon as the donor tanker hull arrived at the anchorage in Singapore, with a team mobilized to the vessel for a detailed inspection and familiarization of the vessel.

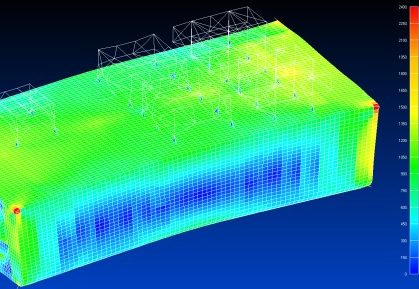

Conversion engineering scope, covered the in-place analysis of the unit as well as transportation of the unit to site. Site specific analysis included the motion analysis of the FPU whilst moored at site, intact and damage stability and an ISE/TSA hull global strength assessment using FEMAP software.

In addition to the hull engineering, Longitude provided designs for the topsides equipment supports (module weighing up to 900 tonnes each), a new Helideck, Flare Tower, crane pedestal and boom rest, 12 new chain stoppers, a new offloading platform and a new Riser and Umbilical I-tube balcony, all including the foundation and interface with the deck. In providing these designs, strength and fatigue analysis and construction drawings were provided. In all cases full ABS approval of the analysis and drawings was obtained

Throughout the project, Longitude’s engineers were able to provide general support to BW Offshore project management team and fabrication support to Sembawang Shipyard to ensure the success of the project.