Case Study

Home » Case Studies »

Design of Decommissioning and Removal of MOPU Cendor and Associated Wellhead Structure with Conductors

The CENDOR MOPU PRODUCER was installed in Cendor field in 2006 to produce from the field until such time as further field infrastructure is installed and decommissioned. It is proposed that the MOPU be decommissioned and removed between July and October 2014.

Facts and Figures:

- Global Process System Sdn Bhd (GPS), Sapura Kencana and Petronas

- Spud Can Jackup

- Limited marine spread and lifting capacity on site

- ABS Class

Longitude’s Scope of Work

Longitude is in the process of designing the decommissioning and removal of a MOPU and associated wellhead structure with conductors offshore Malaysia.

This structure was designed as a Mobile structure but once in place the conductors were piled through the well head structure making it a fixed structure. Longitude was engaged by the MOPU owners to plan and design the decommissioning and removal of the MOPU. The well head structure was owned by the oil company who had plans for the removal of the structure, however, upon review of those plans it was discovered that the proposed methods were not feasible. As a result, the oil company independently contracted Longitude to attend offshore and inspect the WHS and to develop a plan for the safe remove of the structure, leaving the live conductors in place to be tied back to a new jacket structure. The plan involved the removal of primary, secondary and tertiary steel to enable the structure to be lifted off around the xmas tress as well as design of temporary support structures to take the whole weight of the WHS whilst primary members were cut to detach the WHS from the MOPU.

Longitude’s personnel were in attendance offshore to witness the deconstruction of the WHS and the successful lift of the WHS (with xmas trees and conductors remaining in place). The above photograph illustrates the WHS being lifted off. Longitude was involved in the execution of the MOPU removal which involves re-floating a jack-up rig that has be on station for 8 years. Next few pages describe the main issues during re-floating of the MOPU.

Re-floating of CENDOR MOPU

Re-floating of the hull ever been an easy job after 8 years in air. Serious corrosion can be happened to hull external and tank internal structures due to lack of maintenance. Watertight integrity become a major issue in this MOPU demob, although temporary repair is acceptable to most of classification societies for single voyage, repair of hull shell and watertight bulkhead at offshore are a time consuming work, it became a major factor in cost impact.

Leaks were found and we have to jack the hull out of water for repair two times, and it spent one week time to fix leaks but doubler patches.

It is a good practice to test tank watertight integrity by compressed air before jacking down.

CENDOR MOPU was converted from drilling rig. Drill water tank, Salt water tank and Mud tank became void spaces as a MOPU, those tanks may be used as seawater ballast tank during transit, the tank structure can be heavily corroded if the tank did not been cleaned and keep dry.

Before lifting of Well Head Support Frame, conductors were reinforced by clamps (yellow colour structures in picture). Strength of self-standing conductors is to be engineered.

In 63m water depth, deflection of conductors can be as much as 300mm due to wind, wave and current forces, sufficient clearance between WHSF and X-mas tree shall be considered in lifting design.

Lifting guides shall be provided to avoid crash between WHSF and MOPU.

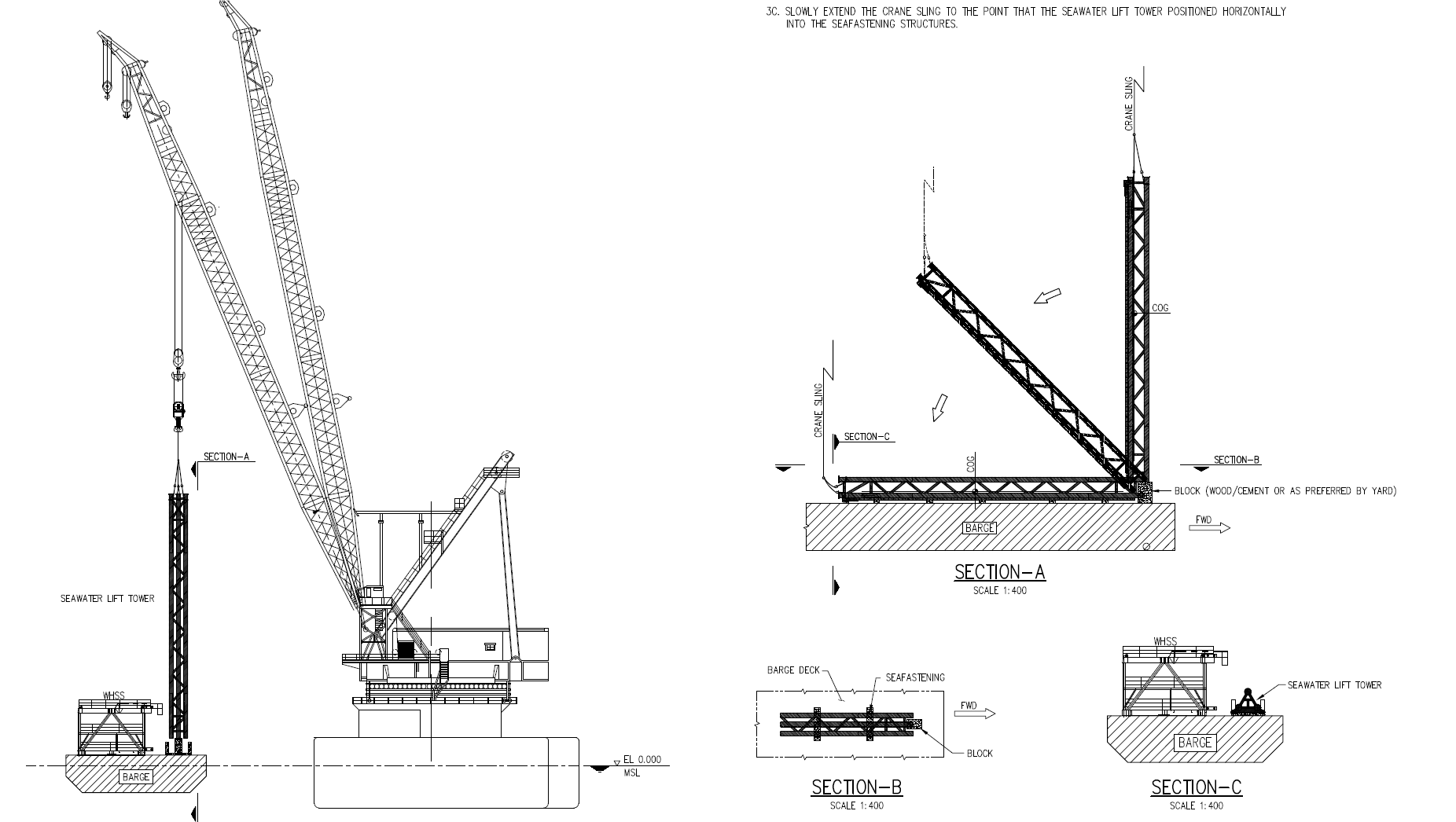

Remove of Sea Water Lift Tower (SWLT).

A temporary submersible pump is needed for sea water supply (for cooling and water maker) after removal of SWLT.

SWLT was removable type structure by slot-in sockets. Due to corrosion and unexpected weldings, the crane was unable to pull up the SWLT during lifting, so the pins have been cut during removal. Scaffolding is required for access for cutting.

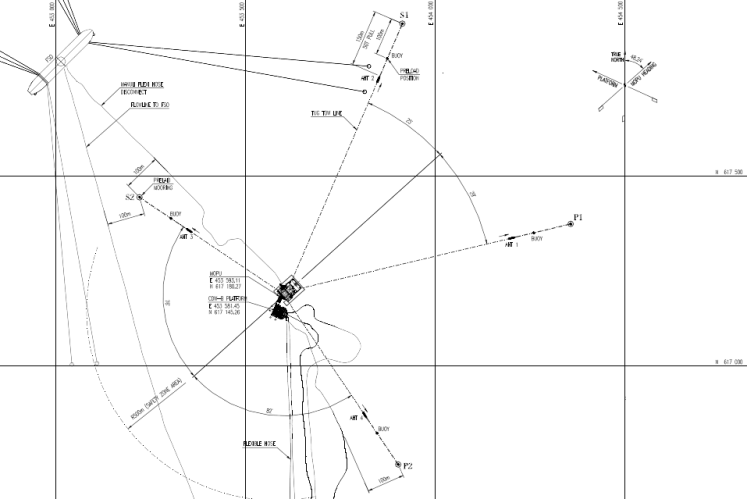

4 points mooring system was set up for float off, live conductors at stern of the hull is very close to topside hull and need to be take care of. Dynamic Positioning System was set up on pulling tugs and on MOPU, computer screen are placed in jacking control room as well as in radio room, allow rig mover to monitor the motion of MOPU.

High resolution and site specific marine weather forecasts covering the period of next five days shall be transmitted daily to the Rig mover and to each tug.

For Positioning and Jacking down to re-floating, following weather criteria was set:

Wind speed: 15 knots

Significant Wave Height: 1.0 m

Max. Surface Current: 1.0 knot

Visibility: 1000 m

Marine Traffic: 500 m (exclusion zone)

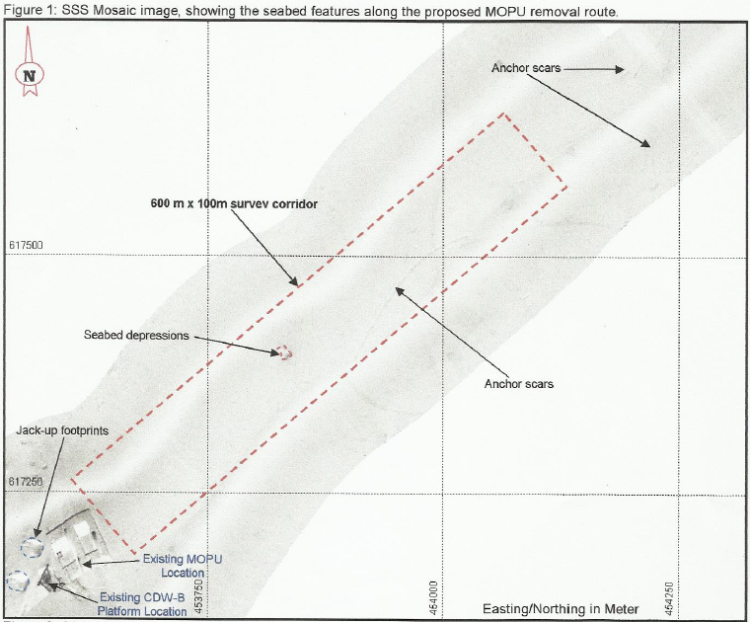

Design of mooring arrangement should take care of subsea properties. Anchors should not be placed within 100m of a subsea asset. For mooring line pull towards the subsea asset, the anchor to be located more than 300m away from pipeline or cable. Vertical clearance of mooring line should be more than 10m from subsea asset at any tension. Surface buoy can be used if needed.

After re-floating, keep mat close to seabed as much as possible, in case of emergency, mat can be deployed on seabed and jack hull out of water immediately. ie, if hull leakage found.

Seabed scan is to be carried out along MOPU removal route. Location suitable for mat deployment is to be defined.

Condition of mat tanks is always an uncertain part. Fatigue crack in connection of leg to mat structure is found common on this type of MOPU, permanently buoyant mat tanks around leg might flooded due to crack. Flooding of mat tank will affect the floating draft.

Once hull watertight integrity was confirmed, mat was bring up to sea surface for diving survey. It need about 10 hours to bring the mat up to sea surface.

Minimum separation between topside hull and mat is 2.5 ft. larger separation (ie, 13.0 ft) is need allow diver to access to top of the mat.

Underwater survey on mat structure shall carry out right after mat was brought up to sea surface, both top and bottom of the mat shall be inspected, to find any damages or cracks, and also to know the situation of the mat, ie, marine growth, and any mud stuck on bottom of the mat.

The midship draft may be found deeper than the assigned loadline, if so a single voyage loadline certificate will be needed for port clearance.