Case Study

Home » Case Studies »

North Oil Company | Case Study | Longitude

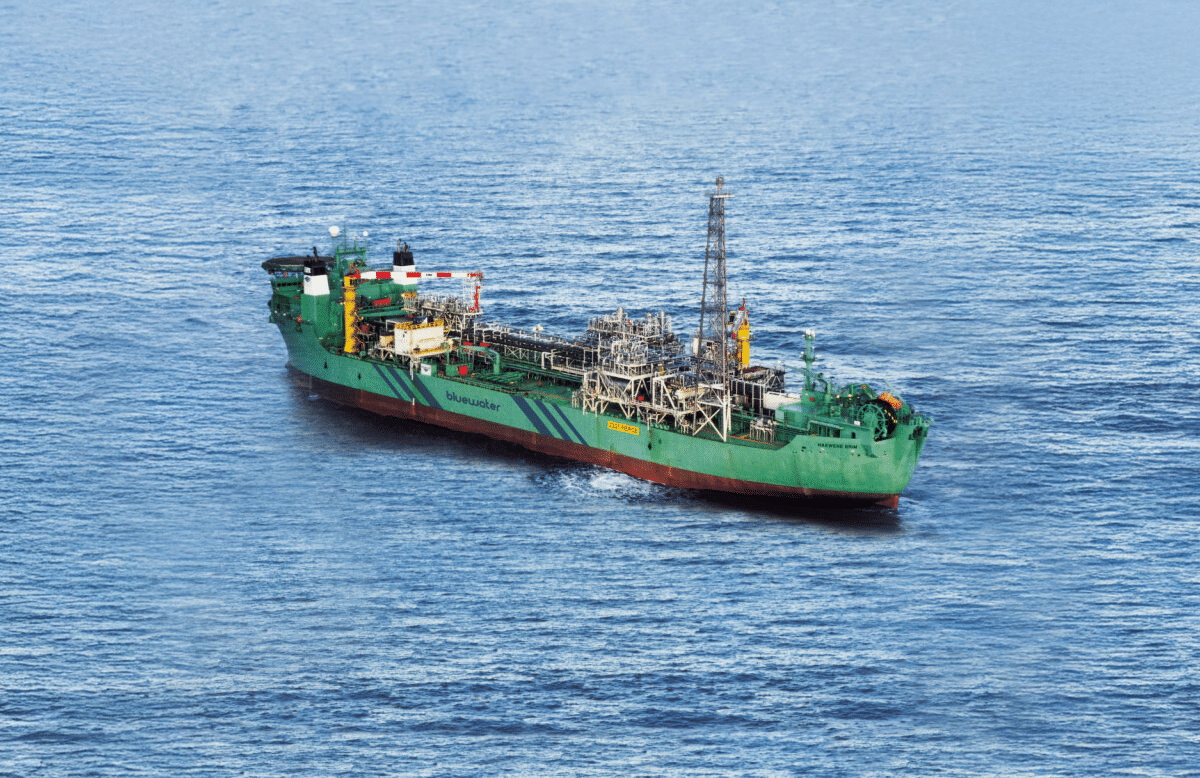

Emergency VLCC Conversion to FSO

Longitude was engaged by the client to scope a conversion dossier for a very large crude container (VLCC) to a floating storage and offloading unit (FSO) in an emergency situation for deployment in the Al Shaheen field in the Persian Gulf.

The Al Shaheen field is Qatar’s largest oil field. It is a conventional oil field (60 m WD) situated offshore Qatar, approximately 70 km NNE off Ras Laffan.

Al Shaheen oil production is gathered in two main locations, A and B, and exported, via Pipeline End Manifolds (PLEMs) and Single Point Moorings (SPMs), to two Ultra Large Crude Carriers (ULCC) Floating, Storage & Offloading Units (FSOs) – respectively FSO Asia and FSO Africa.

Scope of work

Longitude provided a comprehensive scope of conversion dossier for the major systems and equipment to enable the conversion of the Very Large Crude Carrier (VLCC) to an FSO including:

- Scope of conversion dossier, including cost and schedule

- Mooring assessment

- Arrangement drawings for GA, capacity plan, accommodation

- Vent mast, escape and evacuation plan, hazardous area plan & fire and safety plan

- Tank coating assessment and tank anode study

- Hawser and export hose stowage solutions

- Machinery and pump room arrangements

- Updated equipment list

- P&IDs for cargo system, inert gas system, stripped and produced

- Water system, domestic water system, black and grey water system & fire and foam system

- Electrical load assessment

- Review of PAGA system and fire and gas detection system

- Functional specification for produced water treatment and produced water export

Results

A concept business case study was developed that gave the cost and timeline with all scopes to convert the VLCC into an FSO.

This allowed for business approval to move into the FEED stage of design.